How to Enhance the Durability of Stainless Steel Bearings Through Salt Spray Testing?

Exhibitor: JOTA BEARING CO., LTD

Date: 2025-06-20

Booth No.: S830

1. How to enhance the durability of stainless steel bearings through salt spray testing?

In modern industrial applications, the durability and stability of stainless steel bearings are crucial. To ensure our stainless steel bearings maintain excellent performance in various harsh environments, we employ rigorous salt spray testing to assess their corrosion resistance.

2. Using high-performance materials

%E4%B8%BB1688.jpg)

Our stainless steel bearings are made from high-performance materials such as SUS440C, SUS304, and SUS316. These materials are renowned for their excellent resistance to acids, alkalis, corrosion, and high temperatures, ensuring stable performance even under extreme conditions.

- SUS440C:High hardness and wear resistance, suitable for use in high load and high-speed environments.

- SUS304:Possesses excellent corrosion resistance, suitable for general industrial applications and humid environments.

- SUS316:Due to its molybdenum content, it offers excellent resistance to pitting and crevice corrosion, making it particularly suitable for use in marine environments and the chemical industry.

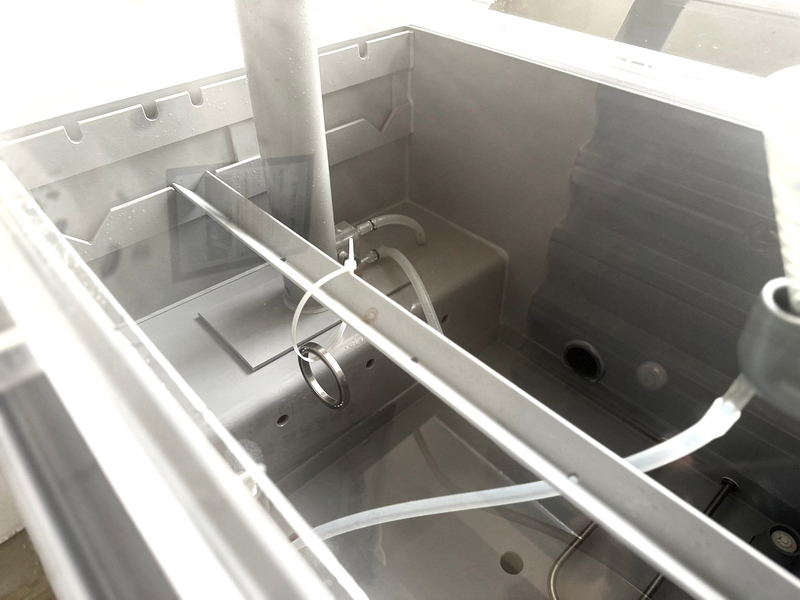

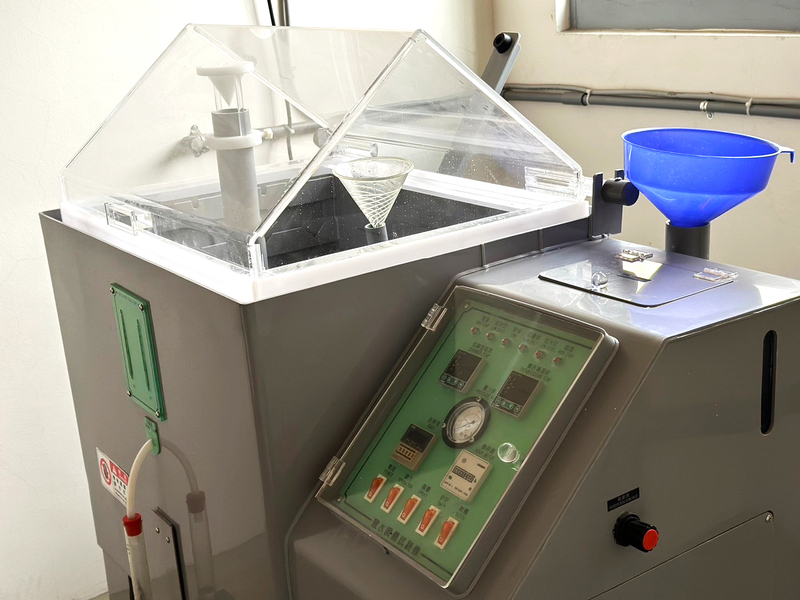

3. Rigorous salt spray testing

Salt spray testing is a method used to simulate corrosive environments, evaluating the durability and stability of stainless steel bearings. We use salt spray testing to ensure these materials can perform well in corrosive mediums. Specific test environments include:

- Sea water:Simulates corrosion conditions in marine environments.

- Distilled water:Testing the corrosion resistance of bearings in pure water.

- Dilute nitric acid:Testing the durability of bearings in acidic environments.

- Marine climate:Simulates humid and salt spray environments.

- Steam:Testing stability in high-temperature and high-humidity environments.

4. Improving equipment operational efficiency

With our stainless steel bearings tested under salt spray conditions, your equipment will operate for longer durations in the most severe environments, significantly reducing maintenance frequency and costs. This not only enhances overall operational efficiency but also ensures excellent performance under high-pressure and low-load conditions.

5. Reliable performance and long-lasting durability

Our stainless steel bearings undergo rigorous salt spray testing to ensure they perform exceptionally well in corrosive environments. This means that under high-pressure and high-load operating conditions, your equipment can maintain stable operation, thereby improving production efficiency and reducing operating costs.

By choosing our stainless steel bearings, you will have a reliable and durable solution, ensuring your equipment operates efficiently even in the most demanding environments. Let's work together to enhance equipment efficiency and achieve optimal performance across various industrial applications.

More Exhibitor's Press Release

- Dexmart Unveils Modular Robot Joint Modules at the 2025 Taipei International Automation Exhibition DEXMART TECHNOLOGY CORPORATION / 2025-10-12

- ISDN Precision System Debuts at Automation Taipei 2025 Featuring Nano-Level Motion Solutions ISDN PRECISION SYSTEM CO., LTD. / 2025-09-05

- Metal Stamping Is More Than Just Processing: Aotron Transforms Manufacturing Value Through Precision AOTRON INDUSTRIAL CO., LTD. / 2025-08-28

- Can Metal Stamping Be Both Gentle and Precise? Aotron Has the Answer AOTRON INDUSTRIAL CO., LTD. / 2025-08-28

- 42 Years of Precision Stamping Expertise: AOTRON Embodies the True Craftsmanship of Metal Stamping AOTRON INDUSTRIAL CO., LTD. / 2025-08-28

- Super Air – From Workshop Roots to an Energy-Saving Leader, the AMG of the Air Compressor Industry SUPER AIR COMPRESSOR TECHNOLOGY CO., LTD. / 2025-08-26

- Power Micro Uses Nano-Particle Surface Modification to Reduce Adhesion in Metal and Plastic Tooling POWER MICRO INTERNATIONAL CO., LIMITED / 2025-08-23

- One Turn, Fully Secured — Weishiun Combination Screws Double Your Efficiency WEI SHIUN FASTENERS CO., LTD. / 2025-08-21

- Seeing the Unseen Details — WEISHIUN’s Precision Micro Screws Supporting the Demands of Automation WEI SHIUN FASTENERS CO., LTD. / 2025-08-21

- Beyond Fasteners — WEISHIUN’s All-in-One Screw Solutions for Automation WEI SHIUN FASTENERS CO., LTD. / 2025-08-21

- TN Nameplate at the Automation Show —Come Visit Us Now!! SOUTH EAST ENGRAVE BOARD CO., LTD. / 2025-08-21

- Southeast Nameplate Co., Ltd. to Exhibit at 2025 Taipei Nangang Automation Show, Showcasing Advanced SOUTH EAST ENGRAVE BOARD CO., LTD. / 2025-08-21

- SPiDER EXTRUSION invites you to attend 2025 Taipei International Automation Industry Exhibition! SPIDER INDUSTRIAL CO., LTD. / 2025-08-21

- SPiDER EXTRUSION seeks global distributors and partners for extrusion applications SPIDER INDUSTRIAL CO., LTD. / 2025-08-21

- Power Micro Drives Green Semiconductor Manufacturing with Particle & Alkaline DI Water Tech POWER MICRO INTERNATIONAL CO., LIMITED / 2025-08-21

- APL210N APL310N ITS300 ALS10 Display Micro Switch Taiwan General Agent DDD CO. Valve Industry PIN CHING AUTOMATIC VALVES CO., LTD. / 2025-08-19

- SMC IP8000-031|IP8100-031-DH PIN CHING AUTOMATIC VALVES CO., LTD. / 2025-08-19

- iO-Link | Hart Communication Protocol | Control Valve Positioner Expert Pinqing Valve Industry PIN CHING AUTOMATIC VALVES CO., LTD. / 2025-08-19

- Specializing in linear electric proportional control valves | electric proportional diaphragm valves PIN CHING AUTOMATIC VALVES CO., LTD. / 2025-08-19

- Over 40 years of experience in automatic valve production, with complete certifications PIN CHING AUTOMATIC VALVES CO., LTD. / 2025-08-19