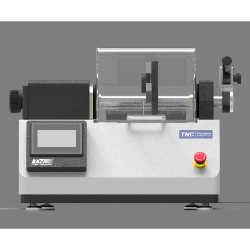

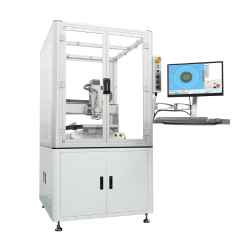

Benchtop Precision Metallographic Cutting Machine

Model: TNC-B

Category: Industrial Automation

Exhibitor: TAIWAN NAKAZAWA CO., LTD.

Booth No: J1026

Characteristic

TNC-B Benchtop Precision Metallographic Cutting Machine

Flexible Operation · Low-Stress Cutting · Ideal for Batch Processing

Product Overview

The TNC-B is a benchtop precision cutting machine specifically designed for material research and metallographic sample preparation. Equipped with a direct-drive motor and multiple cutting modes, it can flexibly handle various materials and cutting requirements. With three operating modes—abrasive wheel cutting, flat-bed cutting, and gravity-fed slow cutting—it significantly enhances cutting precision while minimizing thermal effects and deformation. This makes it an ideal solution for laboratories and quality control departments.

Key Features

Offers three cutting modes: manual arm abrasive cutting, flat-bed straight-feed cutting, and gravity-loaded slow cutting, adaptable to different material properties and precision requirements

Weight-controlled vertical feed ensures stable and consistent cutting pressure, minimizing user error and thermal deformation

Supports efficient batch processing of same-sized samples using a cutting platform, significantly improving sample preparation throughput

Built-in 2.5-liter water tank with recirculating coolant system and quick-release nozzle for easy maintenance and cleaning

Compact benchtop design saves space and features user-friendly screw and handwheel adjustments, making it suitable for schools, R&D centers, and laboratory environments

Applications

Cutting of metallic materials

Soft materials such as PCBs and ceramics

Sampling of heat-treated specimens

Pre-processing for quality inspection and analysis

Preparation of metallographic specimens in laboratory settings

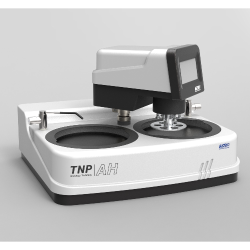

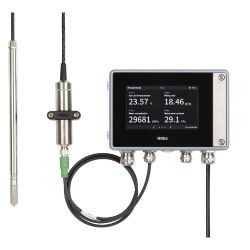

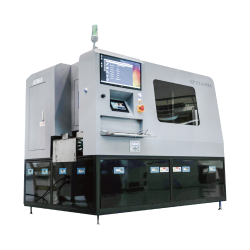

Other Products

Products you may be interested in

Highest Rated Products