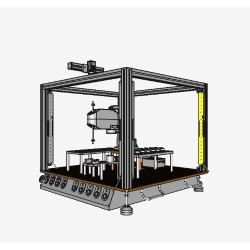

Smart Micro Factory

Model: SMF

Category: Smart Factory

Exhibitor: JYTC CO., LTD.

Booth No: S1012

Characteristic

Challenges:

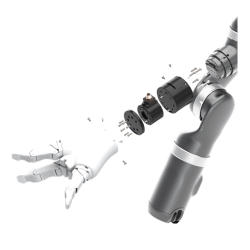

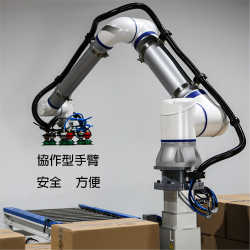

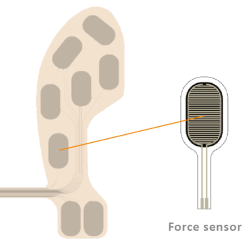

In labor-intensive industries, the lack of skilled workers and high precision requirements are driving the automation process of the manufacturing industry. However, most industrial robots are too large and heavy to handle components that only weigh a few grams. Collaborative robots and other small non-industrial robots lack the high precision needed to handle these delicate and precise parts. Furthermore, the systems must be small enough to fit existing workbenches. While customized linear XYZ platforms may be considered for certain applications, many require at least 5 or 6 degrees of freedom, necessitating the use of articulated robotic arms. These systems also need to be modular, easy to program, and capable of integrating and communicating with various types of other equipment. To meet these demands, JYTC has developed the concept of a smart micro factory centered around the Meca500. These modules (also referred to as workstations) can be equipped with different AI industrial cameras, flexible feeders, advanced force sensor, and other standard and custom measuring equipment. These modules can be combined for various processes to form entire production lines.

Results:

1. Improved product quality - 5um high repeatability, 1um resolution

2. Space saving - high efficiency of area utilization

3. Energy savings - ultra-low consumption of 30W (compared to linear motors)

4. Cost savings - standardization and flexibility

Other Products

Products you may be interested in

Highest Rated Products